In a previously created guide, we showcased how you can use Key Performance Indicators to track the overall effectiveness of your organization, focusing mostly on customer satisfaction and customer support statistics. While that is a very common interpretation of how KPIs can be applied to support your business, it’s far from the only way. To maximize organizational efficiency and service delivery, you should also consider monitoring how you manage inventory.

What is an Inventory Management KPI?

Like any other monitoring system, the specific Key Performance Indicators implemented by your organization will vary depending on how you manage your inventory. Fundamentally, the KPIs you’ll want to implement will enable you and your team to establish clear benchmarks for the items you’ve purchased, and will help to minimize future bottlenecks, whether in network growth or customer acquisition.

Inventory Management KPIs will broadly be split into 3 categories:

- Sales KPIs

- Operational KPIs

- and Receiving KPIs

While each of these categories focuses on different stages of the acquisition process, they help capture an overall picture of how your inventory is moving through the various stages of its lifecycle.

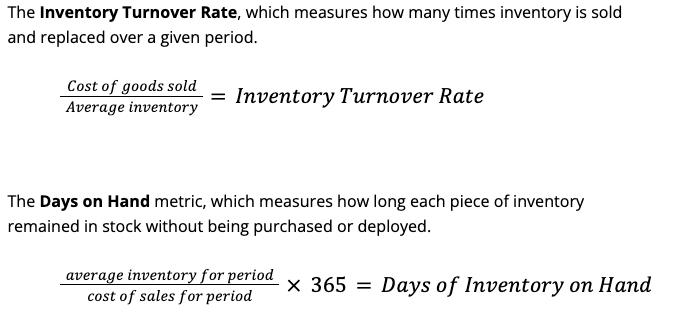

Sales KPIs will serve to track the typical amount of inventory purchasing and inventory demand within a certain time frame. Think of the typical Sales KPI for inventory management as a way to track the cost and revenue derived from the acquisition or sale of your organization’s inventory.

Operational KPIs will serve to track the overall inventory behavior in your organization within a certain time frame. Operational KPIs are the ones that generally deal the most directly with efficiency, existing as a way to directly monitor inventory usage.

Lastly, Receiving KPIs will serve to track the overall incoming inventory handling, allowing you to closely monitor the inbound inventory items shipped to your warehouses. Implementing Receiving KPIs will facilitate the automation of inventory ordering and facility organization.

Choosing the Right KPI Metrics

Now that you have a basic understanding of the KPI categories, it’s important to consider which ones apply best to your organization. Inventory upkeep can be a challenge for even the largest Internet Service Providers. This is due to the sheer amount of inventory flowing through warehouses, which is necessary to maintain network infrastructure, deploy new serviceable areas, and provide equipment to customers. Without implementing some way to measure inventory metrics, it’s possible to get lost in the weeds of ordering more and more inventory without having deployed a sufficient amount to recoup your expenditure.

Choosing the right KPIs for your inventory management is critical to implementing continuous improvements and for promoting continuous growth, and not all metrics will apply to every organization. Below, you’ll find some examples of common Inventory Management metrics, along with some equations to help you implement them.

Sales Metrics:

Similarly, there exists a “weeks on hand” metric, where the equation is multiplied by 52 rather than 365.

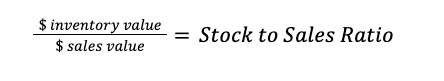

The Stock to Sales Ratio metric, which measures the percentage of items in stock that are being sold versus kept on hand.

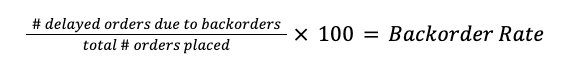

The Backorder Rate metric, which identifies the number of backorders as a percentage of total orders in a given time period.

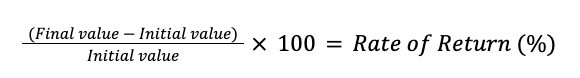

The Rate of Return metric, which measures the net loss or gain of your purchases within a specific time period.

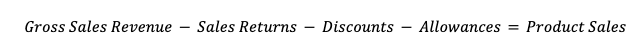

The Product Sales metric, which measures the final revenue of all inventory sales after factoring in returns and discounts.

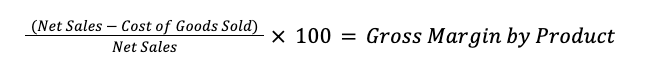

The Gross Margin by Product metric, which identifies the overall profit margin percentage based on the overall item sales your organization made in a given period.

Operational Metrics:

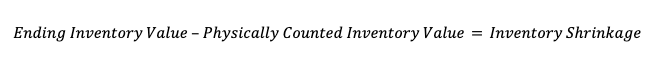

The Inventory Shrinkage value, which measures the difference between initially counted inventory and final inventory counts within a time period.

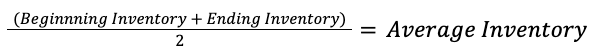

The Average Inventory metric, which will show you the average amount of in-stock inventory within a time period.

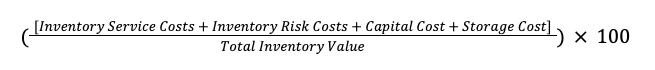

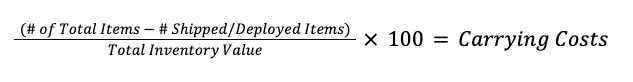

The Inventory Carrying Costs metric, which measures the total cost of storing unsold or undeployed inventory.

The Fill rate, which measures the amount of orders (or jobs) you’re able to fulfill without running out of inventory.

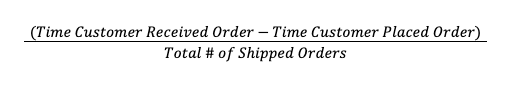

The Order Cycle Time, which measures the amount of time it takes to fully fulfill an order.

Receiving Metrics:

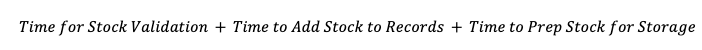

The Receiving Efficiency metric, which provides a quick way to measure the time between receiving items from a Purchase Order, and having them ready for sale or deployment on your network.

![]()

The Time to Receive metric, which will measure the overall time it takes to prepare a received item for sale or deployment, rather than the time between these activities.

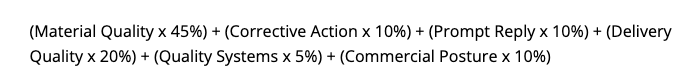

The Supplier Quality Index metric, which is a way to measure the relative quality of items received from one of your suppliers.

Operational efficiency, financial health, and reputation depend on good business processes, including inventory management. These metrics, while not an exhaustive list, hopefully provide you with some ideas of ways you can implement inventory management systems in your organization. With Sonar, your inventory management module allows you to dynamically measure and extract relevant data. With the built-in Business Intelligence Reporting, you’ll be able to schedule in-depth reports that will contain the information needed to generate the KPIs you determine fit your business needs. For more information on how Sonar’s Inventory and Reporting modules can benefit your business, reach out to [email protected].